Servo Liquid Filling Machine

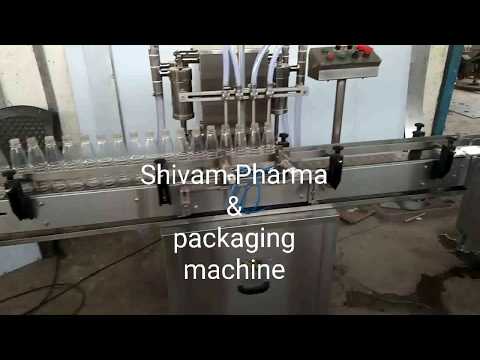

Automatic Servo 6 Head Liquid Filling Machine

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Automatic Servo 6 Head Liquid Filling Machine |

| Others: | |

| Capacity | 40-50 1ltr |

| Driven Type | Electric, Hydraulic |

| Voltage | Single Phase |

| Warranty | 1 year |

| Weight | 1.5 ton |

Automatic Servo Base Liquid Filling Machine

Brand:

Others

Price ₹

6,50,000.00

| General Details: | |

| Model | Automatic Servo Base Liquid Filling Machine |

| Others: | |

| Filling Range | 200ml to 5ltr |

| Filling Range | 200ml to 5ltr |

| Power | 220 volt |

| Usage/Application | to fill oil, paint or other liquid |

| Voltage | Single Phase |

| Brand | SHVAM |

| Capacity | 40-45 |

| Driven Type | Electric, Hydraulic |

| Filling Accuracy | +-0.1% |

| Filling Head | 6 head |

Automatic Servo Liquid Filling Machine

Brand:

Others

Price ₹

6,50,000.00

| General Details: | |

| Model | Automatic Servo Liquid Filling Machine |

| Others: | |

| Capacity | 30 BPM |

| Country of Origin | Made in India |

| Driven Type | Electric |

| I Deal in | New Only |

| Nozzle Type | ss round nozzle |

Automatic Eight Head Servo Filling Machine

Brand:

Others

Price ₹

9,50,000.00

| General Details: | |

| Model | Automatic Eight Head Servo Filling Machine |

| Others: | |

| Capacity | 12 TO 40 BOTTLES / MIN. |

| Country of Origin | Made in India |

| Model Name/Number | SSFM250 |

| Warranty | 1 Year |

Automatic servo based Paint Filling machine

Brand:

Others

Price ₹

7,80,000.00

| General Details: | |

| Model | Automatic servo based Paint Filling machine |

| Others: | |

| Automation Grade | Automatic |

| Country of Origin | Made in India |

| Driven Type | Electric |

| Material | Stainless Steel |

| Usage/Application | Industrial |

if you are interested, please fill the below details: