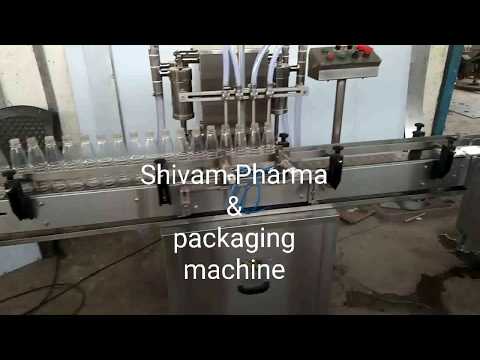

Juice Filling Machine

Automatic Juice Filling Machine

Brand:

Others

Price ₹

2,20,000.00

| General Details: | |

| Model | Automatic Juice Filling Machine |

| Others: | |

| Capacity | 25 BPM |

| Frequency | 50hz |

| Machine Type | Automatic |

| Packaging Type | wooden |

| Phase | 1 phase |

| Power Consumption | 1.75 kw |

| Total Power | 2-2.50 hp |

| Usage/Application | Juice |

if you are interested, please fill the below details: